Paving the Way for a Cleaner, Greener Energy Future

ABSTRACT: Low-emission hydrogen, particularly green hydrogen produced through electrolysis, is emerging as a cornerstone of the global transition to net-zero emissions. Major projects like Saudi Arabia’s NEOM Green Hydrogen Project and Oman’s Green Hydrogen Project are leading this charge, with large-scale electrolyzer installations on the rise. However, as these projects grow, they demand larger electrical transformers, which in turn require enhanced safety standards to avoid catastrophic incidents. This article explores the critical role of safe and reliable transformers in the hydrogen economy, emphasizing how advanced safety systems, such as the TRANSFORMER PROTECTOR™, help safeguard hydrogen production sites. Additionally, we discuss the complexities and challenges faced by hydrogen projects, from regulatory hurdles to safety risks, and how rigorous protection measures ensure compliance and stability.

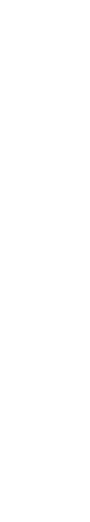

There is widespread agreement that low-emission hydrogen will be crucial in reaching net-zero emissions. Among the options, green hydrogen—produced via electrolysis using renewable energy like solar or wind—has gained significant traction. Its potential applications are vast, ranging from energy storage to use as a fuel in various sectors.

For example, in September 2023, Stuttgart-based H2FLY achieved a major milestone with the world’s first piloted flight of a hydrogen-powered electric aircraft using liquid hydrogen. “This achievement marks a watershed moment in the use of hydrogen to power aircraft,”[1] said Professor Josef Kallo, H2FLY’s co-founder. “Together with our partners, we’ve demonstrated the viability of liquid hydrogen to support medium- and long-range emissions-free flight… We are now looking ahead to scaling up our technology for regional aircraft and other applications, beginning the critical mission of decarbonizing commercial aviation.”[2]

Europe has led the way in hydrogen research and development, especially in patenting technologies that support clean energy transitions. According to the International Energy Agency (IEA), its 2023 report, Hydrogen Patents for a Clean Energy Future, highlights the region’s leadership in hydrogen innovation.

Since the latest Global Hydrogen Review in September 2022, over 3.8 GW of electrolyzer projects have reached final investment decisions (FID) or started construction. This growth is driven largely by the NEOM Green Hydrogen Project in Saudi Arabia, which is the largest of its kind and scheduled to be operational by 2026. In Oman, the Green Hydrogen Project recently achieved financial closure and is expected to produce 100 kt of ammonia per year, with plans to scale to 3.5 GW capacity. Additionally, there is a shift toward larger-scale electrolyzer plants, with today’s average size around 12 MW, expected to grow to hundreds of MW and even 1 GW by 2030. By then, GW-scale projects are set to account for over 75% of announced capacity.

As electrolyzer projects scale in size and power demands, so too do the requirements for larger electrical transformers to support these installations. With increased capacity, it becomes essential to elevate safety standards for transformers to prevent catastrophic failures. According to the U.S. Office of Energy Efficiency & Renewable Energy, “hydrogen production via electrolysis may offer opportunities for synergy with dynamic and intermittent power generation,”[3] but the challenges associated with energy-intensive production underscore the need for efficient, reliable infrastructure. These growing installations deserve the highest safety standards for transformers, given the potential risks involved in supporting hydrogen production.

Despite these advances, many large-scale low-emission hydrogen projects still face significant hurdles. According to an IEA report for the G7 Climate, Energy, and Environmental Ministerial in April 2023, only 4% of announced projects have started construction or reached FID. Key barriers include uncertainty in future demand, insufficient infrastructure for hydrogen delivery, and regulatory ambiguities, which have slowed both decision-making and investment.

Hydrogen’s complexity extends beyond production. As a highly flammable and lightweight gas, hydrogen presents serious safety risks. It ignites more easily than other fuels, and its flames are invisible, complicating fire detection. If a hydrogen leak reaches a transformer, it could cause catastrophic explosions with severe consequences for human safety, financial stability, and the environment. Moreover, such incidents would trigger regulatory investigations, likely resulting in heavy penalties.

In Europe, strict regulations such as the Seveso III Directive (2012/18/EU) impose high safety standards for handling hazardous materials like hydrogen. The directive requires companies to notify local authorities, submit safety reports, and develop emergency response plans. It also emphasizes that operators must take all necessary precautions to prevent industrial accidents and mitigate their impacts on people and the environment, though it doesn’t prescribe the specific tools needed to meet these safety standards.

This is where solutions like the TRANSFORMER PROTECTOR™ (TP) are vital. Integrating TP systems from the project’s initial phase safeguards transformer fleets against explosions and fires. The TP system, developed by Transformer Protector Corp., has been rigorously tested in leading laboratories, such as MEDEF and EDF, and is proven to prevent transformer explosions caused by low impedance failures.

Designed to enhance electrical installation safety, the TP system functions as a rapid depressurization mechanism, isolating the transformer’s oil during incidents to prevent leaks and fires. Its integration can help facilities avoid environmental damage, protect human lives, and minimize regulatory penalties.

Conclusion:

As the hydrogen economy scales up, the need for robust safety standards, particularly for electrical transformers supporting large electrolyzer installations, becomes increasingly important. Projects like Saudi Arabia’s NEOM Green Hydrogen Project and Oman’s ambitious initiatives signal a future where hydrogen plays a key role in decarbonizing sectors like aviation and heavy industry. However, these advancements come with significant safety and regulatory challenges. By integrating advanced systems like the TRANSFORMER PROTECTOR™, hydrogen production facilities can mitigate the risks associated with transformer failures, ensuring both compliance with safety regulations and the long-term sustainability of clean energy initiatives. As the industry grows, maintaining a focus on safety and infrastructure reliability will be essential to supporting this green transition.

- https://www.h2fly.de/2023/09/07/h2fly-and-partners-complete-worlds-first-piloted-flight-of-liquid-hydrogen-powered-electric-aircraft/

- https://www.h2fly.de/2023/09/07/h2fly-and-partners-complete-worlds-first-piloted-flight-of-liquid-hydrogen-powered-electric-aircraft/

- https://www.energy.gov/eere/fuelcells/hydrogen-production-electrolysis